Precision thermometers handmade

In the eXacal manufacture of Klasmeier the precision thermometers are manufactured by careful manual work in Fulda/Germany. In addition to the construction of the actual thermometers, a further focus is the development of our own tools and production processes. For design, production and final DAkkS calibration, no external suppliers are required apart from the raw materials. This independence ensures the high quality of the thermometers.

Mechanical production

Required components, such as handles or prototypes for further development, are manufactured by machining.

Noble metal welding process

Thermocouple wires and connecting cables are welded together precisely by hand. The required fuel gases hydrogen and oxygen are not stored in bottles, but are produced in a 2:1 mixture ratio of water by electrolysis. This guarantees the purity of the fuel gas.

Laser Welding

Particularly filigree connections, such as the connecting wires of the temperature detector, are welded under the microscope with precision lasers.

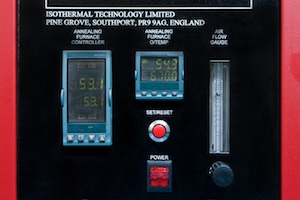

Thermal treatment of thermal material

A core competence is the targeted thermal treatment of thermowires. Our aging processes ensure a metallurgically stable and thermoelectrically homogeneous condition of the eXacal thermocouples.

Annealing of resistance thermometers

Resistance thermometers are completely annealed according to our adapted annealing cycles in a specially designed annealing furnace with oxygen circulation.

3D printing

Insulation elements and complex plastic parts inside the handles, such as strain reliefs, are manufactured using a modern 3D printing process. This offers us many advantages. Complex designs are produced without manual detours and without expensive tools. This saves a lot of time and money. By means of 3D printing, eXacal thermometers can be manufactured as a modular system according to customer specifications.

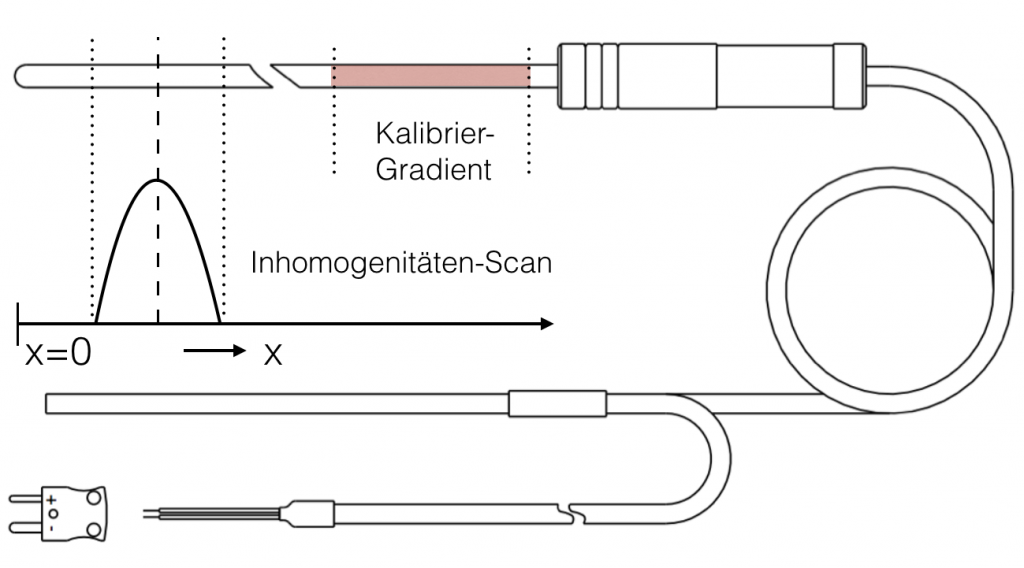

Inhomogeneity Scanner

Possible inhomogeneities of the eXacal thermocouples are examined with the help of an inhomogeneity scanner. A mobile heat source tests the entire thermal material of the measuring point for local inhomogeneities.

The inhomogeneity scanner is a proprietary development of the Klasmeier company. With it the thermocouples of the eXacal manufacture can be improved substantially:

The inhomogeneity scanner is a proprietary development of the Klasmeier company. With it the thermocouples of the eXacal manufacture can be improved substantially:

- More realistic consideration of the measurement uncertainties

- Checking the thermal treatment

- Improvement of quality and manufacturing processes

New eXacal brochure

On 12 pages you will find a selection of our precision thermometers, as well as a presentation of our eXacal manufacture and the technology behind our thermometers.

- Resistance thermometers and thermocouples made in Germany

- Technology and materials used

- eXacal Manufaktur – handmade thermometers

Order your free brochure!